KEY STRENGTH

- Electronically controlled, servo driven in-feed module for single lane product accumulation and synchronization

- Phasing belts to synchronizing products avoiding contact – PRESSURE LESS feeding

- 45° degrees transfer of the products to the pickup position

- Feeding system controlled by laser sensors to adopt machine speed to the product accumulation level

- TWO or FOUR reel holders for the wrapping material with mechanical core locking devices

- Servo motor driven wrapping material reels

- Servo motor driven wrapping material draw off roller to control cut off length and adopt photoelectrical print registration signals

- Servo motor driven wrapping material knife with carbon steel insert for a precise cut and an extended service life

- Double film unwinder with OUTER film longer than INNER film without usage of grippers

- Automatic splicer to change wrapping material reels without stopping the machine

- Saving of wrapping material by “no product –no pa-per”-device

- Discharge chute for wrapped products

- Ejection of

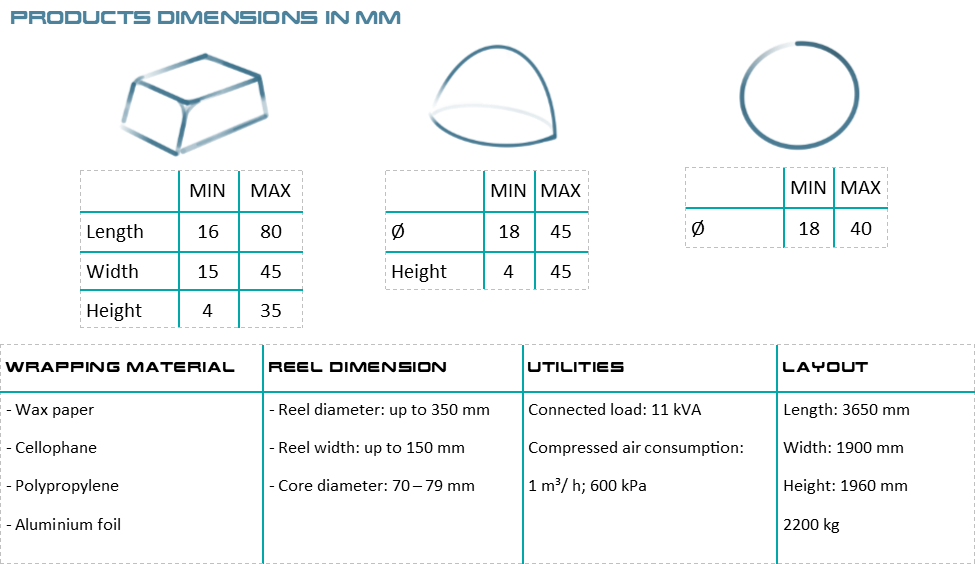

TECHNICAL SPECIFICATIONS

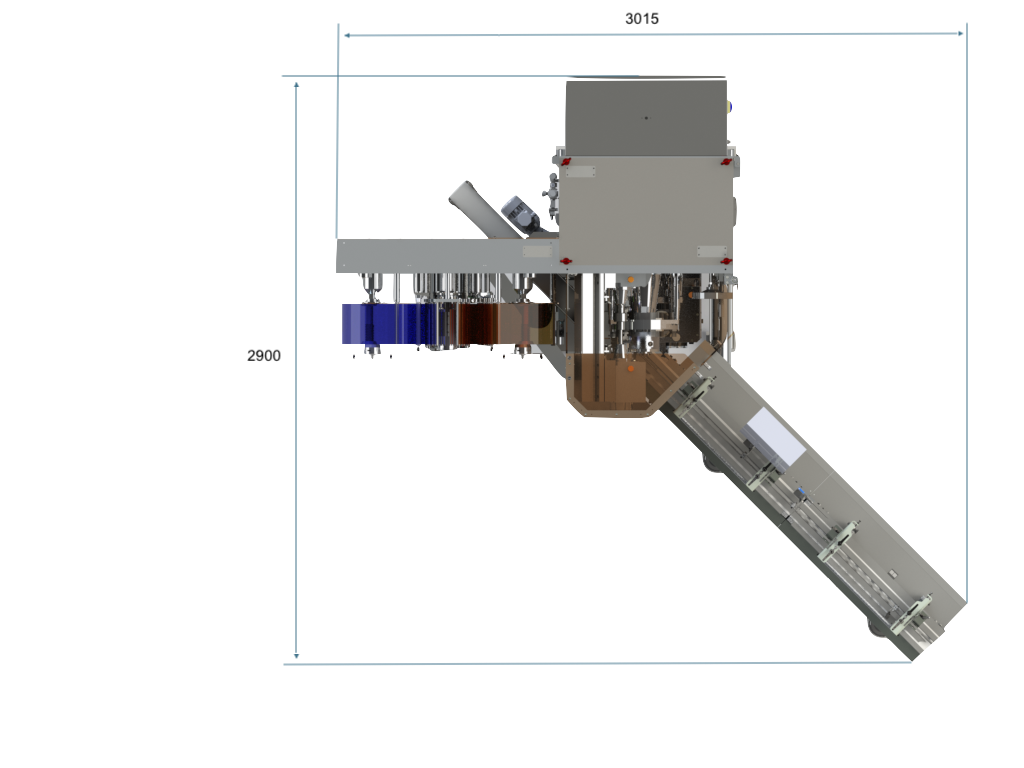

MACHINE LAYOUT

EQUIPMENT AND OPTIONS

- Modular machine design in order to facilitate the chan-ge of wrapping style and/or product dimensions

- Accordingly to the requirements of the products, the feeding system is designed as robotic system with lug chain or as belt feeding system

- Additional reel holders for a second wrapping material (under strip) with automatic splicer

- Wrapping material feed for inner and outer

- Wrapping material with displacement of the inner wrap-per to guarantee a high wrapping quality

- Pneumatic core locking and reel tensioning devices

- Photo-electric print registration

- Defined product discharge

- Glue applicator for tag glue product closure

- Remote diagnostics